The Duct Cross-Section Area Calculator is an essential utility for mechanical engineers and HVAC technicians. It converts dimensions from Rectangular, Round, or Flat Oval ducts into usable airflow data, specifically calculating the Free Area, Hydraulic Diameter, and Equivalent Round Diameter.

Correct duct sizing is the single most important factor in maintaining system pressure, reducing noise, and ensuring energy efficiency.

Calculator Features

1. Three Duct Profiles

It covers every standard commercial and residential duct shape:

Rectangular: Common for main trunks and plenums.

Round: The most efficient shape for airflow friction.

Flat Oval: Space-saving spiral duct often used in exposed ceiling designs.

2. Hydraulic Diameter ($D_h$)

Fluid dynamics equations rely on this value to predict Reynolds numbers and friction loss in non-circular shapes. This tool calculates it automatically.

3. Equivalent Round Diameter ($D_e$)

Using the Huebscher equation, it tells you exactly what size round pipe would offer the same friction loss as your rectangular or oval duct—critical for sizing fans.

The Math

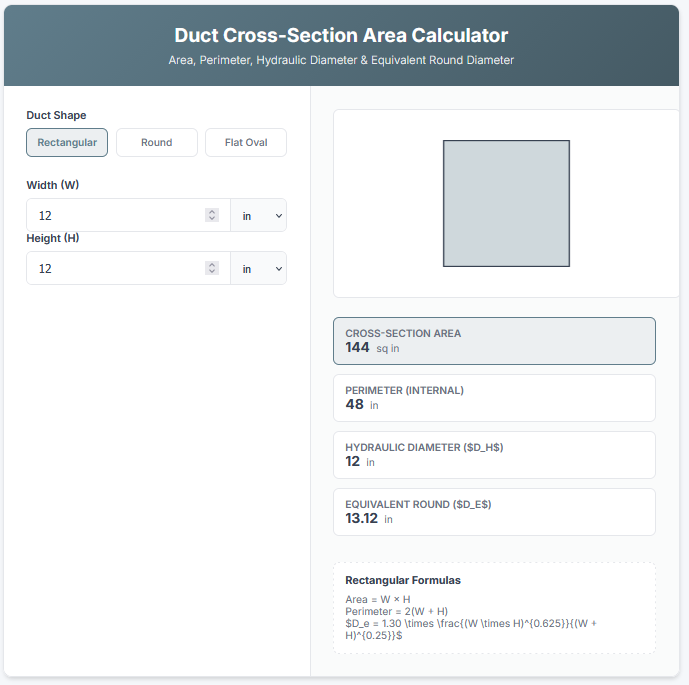

Rectangular Duct

Area = $W \times H$

Perimeter = $2(W + H)$

Hydraulic Diameter

$D_h = \frac{4 \times Area}{Perimeter}$

Equivalent Round Diameter (Huebscher)

For rectangular ducts:

$D_e = 1.30 \times \frac{(W \times H)^{0.625}}{(W + H)^{0.25}}$

Real-World Applications

Retrofitting

When replacing a round duct with a rectangular one to gain ceiling height, use the $D_e$ value to ensure the new flat duct carries the same CFM without increasing static pressure.

Velocity Calculation

To find Air Velocity (FPM), simply divide the Airflow Volume (CFM) by the Cross-Section Area (sq ft) provided by this calculator.

Material Estimating

The Perimeter result helps sheet metal shops calculate the exact square footage of galvanized steel required to fabricate a lineal foot of duct.

Tips

Flat Oval Geometry

A flat oval is mathematically treated as a rectangle in the middle with two semi-circles on the sides. Make sure your “Major Axis” is larger than your “Minor Axis.”

Aspect Ratio

Try to keep rectangular ducts near a 1:1 aspect ratio when possible. High aspect ratios (e.g., 4:1) significantly increase surface area friction relative to the cross-section.

Frequently Asked Questions (FAQs)

1. Why is Hydraulic Diameter distinguishable from Equivalent Diameter?

Hydraulic Diameter is a geometric property used for Reynolds number calculations. Equivalent Diameter is a friction-loss property used for sizing. They are rarely the same number for non-round shapes.

2. Does this account for duct liner?

No. You should input the **internal free dimensions**. If your duct has 1-inch internal insulation, subtract 2 inches from your width and height inputs.

3. What units should I use?

In the US HVAC industry, inches (in) and square inches ($in^2$) are standard for sizing, while airflow is calculated in square feet ($ft^2$). This tool supports both.

Final Words

The Duct Cross-Section Area Calculator is the translator of the HVAC world. It turns physical metal dimensions into the aerodynamic data needed to design quiet, efficient, and balanced air distribution systems.