The Hole Area Calculator is a specialized tool for engineering and manufacturing. It serves two distinct purposes: calculating the "Open Area Percentage" for perforated sheets/screens, and calculating the simple geometric area of single circular or annular holes.

For perforated metal sheets, finding the "Open Area" is critical for airflow, light filtration, and weight reduction. This calculator uses industry-standard formulas for staggered and straight patterns.

Features

1. Perforated Sheet Mode: Calculates the % Open Area based on hole size () and Pitch (). Supports standard patterns: 60° Staggered (most common), Straight Round, and Straight Square.

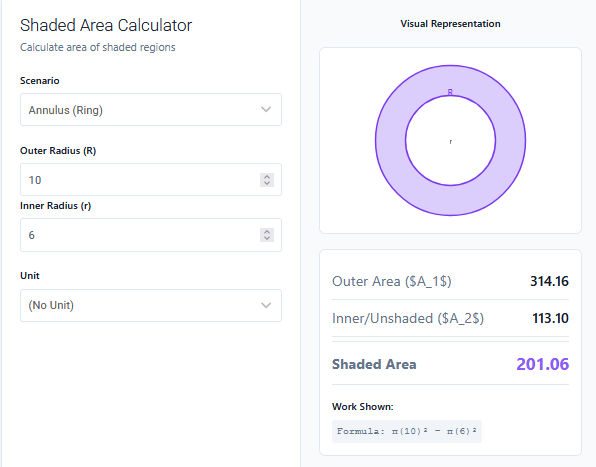

2. Single Hole Mode: Calculates the specific area of a single circle or an "Annulus" (a ring shape, like a washer).

3. Visual Validation: Draws a dynamic diagram of the perforated pattern (e.g., showing the honeycomb staggered layout) or the single hole geometry.

4. Pitch Validation: Prevents errors by checking if the hole size exceeds the pitch (which would mean the holes physically overlap and break the sheet).

5. Industry Formulas: Uses the exact IPA (Industrial Perforators Association) formulas like .

Uses

- HVAC & Acoustics: Designing speaker grilles or ventilation covers where specific airflow (Open Area %) is required.

- Manufacturing: Determining how much material is removed from a sheet during punching.

- Filtration: Sizing sieves and strainers based on hole diameter and throughput.

- Civil Engineering: Calculating net cross-sectional area of hollow structural sections.

Tips

- Pitch Definition: "Pitch" is the distance from the *center* of one hole to the *center* of the next adjacent hole. It is NOT the gap between holes.

- Staggered is Stronger: The 60° staggered pattern is standard because it offers the best combination of high open area and structural strength.

- Annulus: Use the "Annulus" mode to find the face area of a pipe or a washer (Outer Circle minus Inner Circle).

FAQs

What is open area?

It is the ratio of hole area to total sheet area. A sheet with 50% open area cuts the weight in half and allows 50% of air/light to pass through.

Can I get 100% open area?

No, that would mean no material is left! Structural limits usually cap open area around 60-70% for standard sheets.

Why 60 degree stagger?

It creates equilateral triangles between hole centers, which distributes stress evenly in all directions. 45° or straight patterns are weaker in certain directions.

What if my holes are square?

Select the "Square Hole (Straight)" option. The formula changes to .

Final Words

Whether you are designing a sleek speaker grill or a heavy-duty gravel sieve, knowing the Hole Area is about balancing flow with strength. This calculator bridges the gap between simple geometry and industrial specification.