Percent Reduction of Area Calculator

Understanding the Metrics

Percent Reduction of Area (%RA) is a measure of ductility—how much a material can stretch and neck before breaking. High %RA indicates a ductile material (like Copper), while low %RA indicates a brittle material (like Glass or Cast Iron).

True Strain ($\varepsilon$) vs Engineering Strain

ASTM E8 Standard

In materials science and metallurgy, the Percent Reduction of Area (%RA) is a critical measure of Ductility. It quantifies how much a material stretches and narrows (necks) before it finally snaps under tension. Calculated according to standards like ASTM E8, it compares the original cross-sectional area of a test specimen to the smallest area at the point of fracture.

The formula is: . A high %RA means the material is ductile (stretchy, like copper), while a low %RA means it is brittle (snaps easily, like glass).

Features

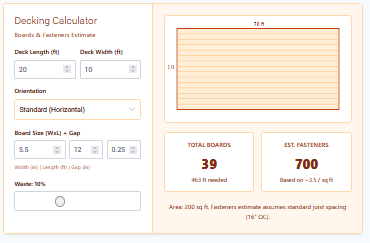

1. Dual Input Modes: Calculate based on Diameter (for standard round test bars) or Area (for irregular shapes).

2. True Strain Calculation: Beyond simple %RA, it computes the True Strain (), a more accurate metric for large deformations used in advanced engineering.

3. Visual Necking Simulation: A dynamic “Dogbone” visualization actually shows the specimen stretching and narrowing based on your inputs, helping students visualize the physical phenomenon.

4. Material Comparison Chart: See where your result lands on the spectrum! The built-in bar chart compares your sample against common materials like Glass (0%), Aluminum (~15%), and Copper (~75%).

5. Estimated Elongation: Provides a theoretical estimate of elongation based on the constant-volume assumption of plastic deformation.

Uses

– Quality Control: Foundries and steel mills use this test to ensure batches of metal meet structural specifications.

– Forensic Engineering: When a part fails, engineers measure the fracture surface. A small reduction in area suggests a brittle failure (unsafe), while a large reduction suggests ductile overload.

– Aerospace Design: Selecting materials that can withstand shock and vibration without snapping requires precise ductility data.

– Education: Perfect for lab reports in “Mechanics of Materials” university courses.

Tips

– Measure the Neck: When measuring the final diameter (), always measure at the very narrowest point of the fracture. This is the “neck.”

– Fit the Pieces: For the most accurate measurement, fit the two broken halves of the specimen back together tightly before measuring.

– Round vs. Flat: This calculator is optimized for round bars. For flat rectangular specimens, use the “Area” mode and calculate manually.

FAQs

What is a “Good” Reduction of Area?

It depends on the application. For structural steel, is common. For car springs, high strength is more important than high ductility. Glass has .

Difference between %RA and %Elongation?

%Elongation measures how much the sample lengthened. %RA measures how much it thinned. %RA is generally considered a more reliable indicator of ductility because it is less affected by the specimen’s length.

Why is True Strain negative?

It shouldn’t be! In compression, strain is negative. In tension (this test), strain is positive. If you get a negative value, check that your Final Area is smaller than your Original Area.

Final Words

The Reduction of Area Calculator brings the material testing lab to your screen. By simplifying the definitions of ASTM E8 into an interactive tool, it helps engineers and students alike understand the vital “personality” of metals—whether they will bend gracefully or break suddenly.